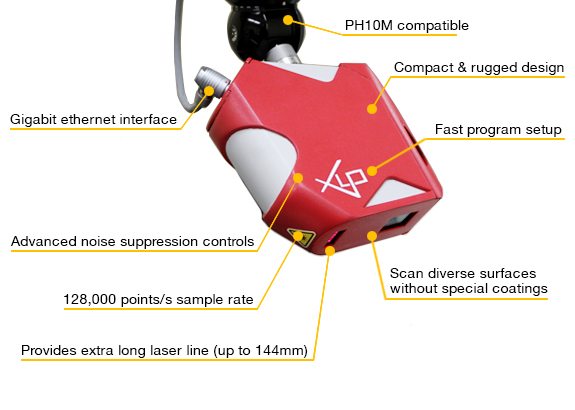

XLP Laser Scanners 250, 500, 1000

The XLP laser scanners are able to scan diverse surface materials without any special coatings, is up to 50% more accurate, up to 70% faster scan rate, and up to 30% higher resolution.

Features

- Industry best accuracy, resolution and speed for laser line scanning technology

- Automated, programmable 3 to 6 axis scanning control

- Factory calibration to NIST traceable

- Advanced noise suppression controls

- Windows 7 and 8 compatibility

Benefits

- Fast program set up

- Ability to scan shiny parts

- 30% improved accuracy and resolution

- Highest speed data collections & shorter inspection times

- Clean room and factory floor compatible

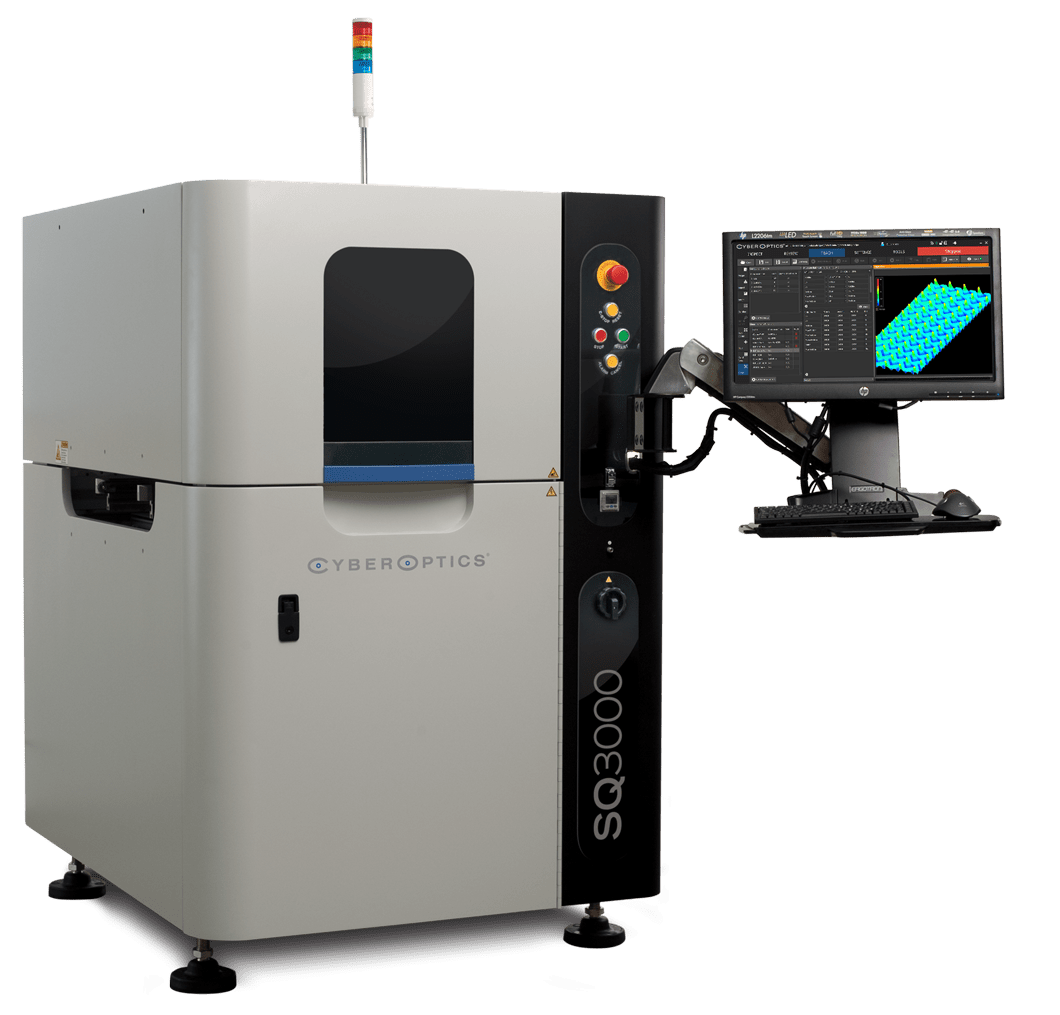

The Ultimate in Speed and Accuracy for Coordinate Measurement Applications – Seconds. Not Hours.

Fast and highly accurate with repeatable and reproducible measurements for metrology applications in the manufacturing of a wide variety of products such as PCBs, semiconductors and consumer electronics.

The SQ3000™ is powered by our parent company, CyberOptics and their breakthrough 3D sensing technology comprising four multi-view 3D sensors and a parallel projector delivering metrology grade accuracy at production speed. CyberOptics’ unique sensor architecture simultaneously captures and transmits multiple images in parallel while proprietary 3D fusing algorithms merge the images together. The result is ultra-high quality 3D images and high-speed inspection.

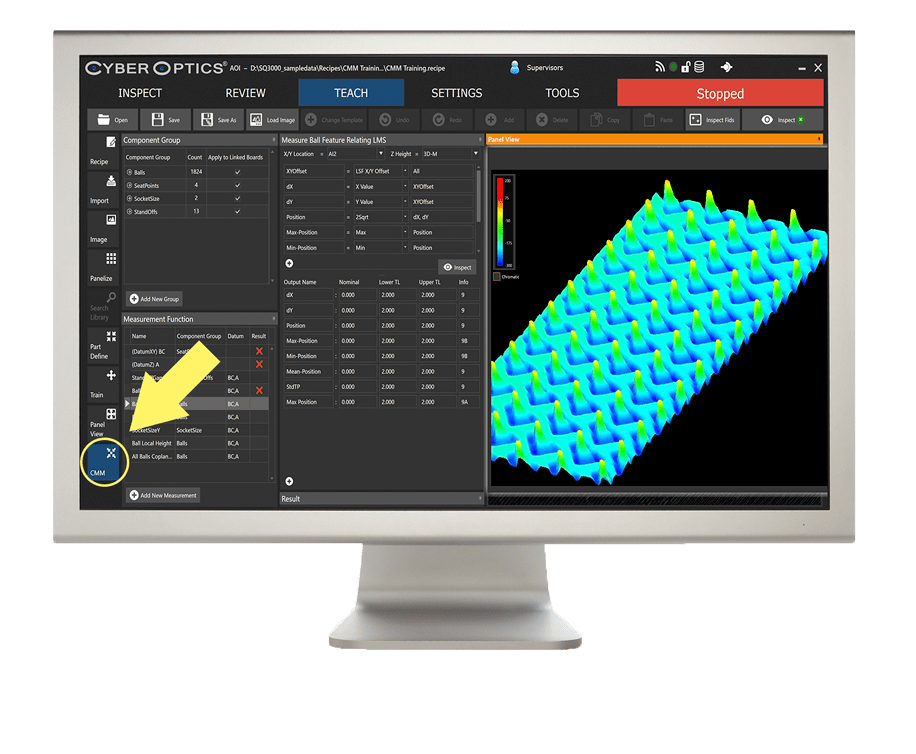

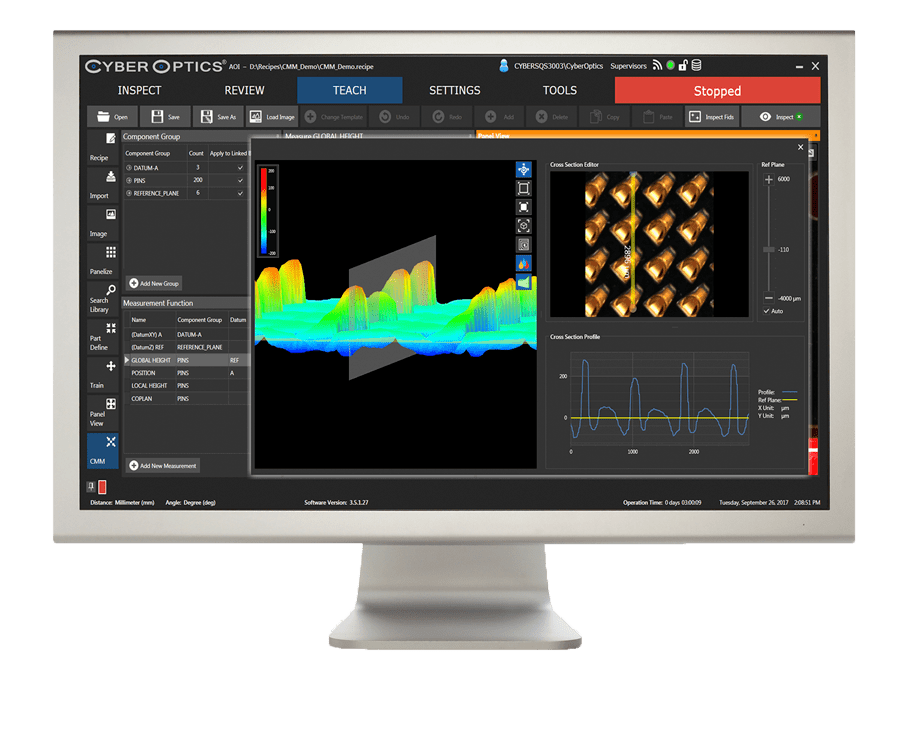

SQ3000 CMM utilizes CyberCMM™, a comprehensive software suite of coordinate measurement tools that provides highly accurate, 100% metrology-grade measurement on all critical points much faster than a traditional CMM, including coplanarity, distance, height and datum X, Y to name a few. A fast and easy set-up can be performed in less than an hour for programming complex applications as compared to slow, engineering resource-intensive set-up that typically requires multiple adjustments with traditional coordinate measurement machines.

SQ3000 3D CMM offers unmatched accuracy with the advanced MRS technology by meticulously identifying and rejecting reflections caused by shiny components making MRS an ideal technology solution for a wide range of applications including those with very high quality requirements.

The Ultra-High Resolution MRS sensor enhances the SQ3000 CMM platform, delivering superior performance ideally suited for Socket Metrology and micro-electronics applications where an even greater degree of accuracy and inspection reliability is critical.

What sets the SQ3000 apart?

Speed:

– Significantly speeds attaining coordinate measurements vs. traditional CMMs

– Reduces engineering resource time

Ease of Use:

– Simplifies process with award-winning, intuitive, touch screen experience

– Quick programming for complex applications

– Multi-process capable – AOI, SPI, AOM, CMM

Metrology-grade Accuracy:

– Achieve metrology-grade accuracy with MRS-enabled technology

– Repeatable and reproducible measurements for metrology, semiconductor, microelectronics and SMT applications.