Master Renishaw Distributor Get Discounts Today

RFM is a master Renishaw distributor. Renishaw products ensuring high-quality metrology solutions for your manufacturing needs. As Renishaw Master Distributors for nearly two decades, we have the expertise and experience to provide superior products and reliable service to our customers. Our online store makes it easy to find and purchase Renishaw products at a discount.

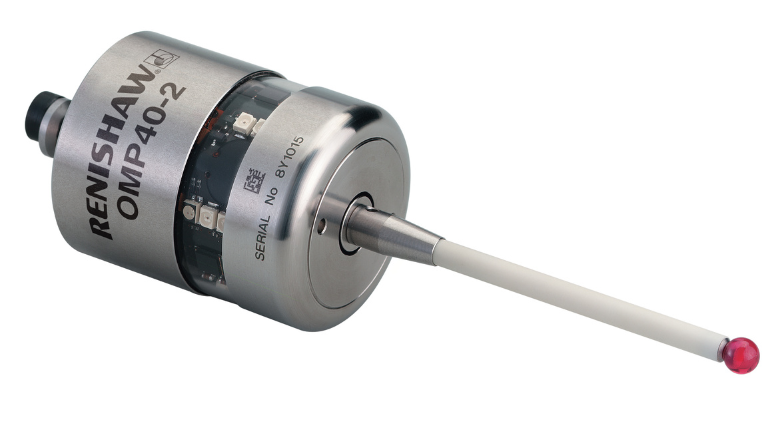

RenishawProbe.com is your go-to destination for authentic Renishaw products. With nearly two decades of experience as Renishaw Master Distributors, we offer a reliable source for all your industrial tool needs. Our commitment to quality ensures that you receive genuine Renishaw CMM Probe Heads, Touch Probes, Probe Shanks, Machine Tool Probes, styli, and accessories.

Have a question about a Renishaw product? Call Us! 937-719-5695

Talk to Us Today

For any questions or assistance regarding Renishaw products, feel free to reach out to us directly. We provide prompt and reliable support to ensure your metrology needs are met efficiently. Contact us today to experience the quality and expertise of Renishaw’s metrology solutions.