Micro-Vu 3D Vision Systems

Explore Micro-Vu's comprehensive range of cutting-edge inspection services at RFM, designed to meet diverse industrial needs. From the versatile fully automated 3D Vertex and Excel to the 2D easy to use VF7, VF1, and HF5 systems. Micro-Vu offers a wide selection of high-resolution camera-based systems equipped with advanced technology for fast and accurate measurements. Experience the reliability and affordability of Micro-Vu's measurement machines, backed by our expertise and quality.

Vertex

Starting at 40,000

Discover the Micro-Vu Vertex Measuring Center, a versatile tabletop system designed for fast and accurate measurements on a wide variety of parts. Equipped with a high-resolution camera-based measuring system, the Vertex offers metrology solutions suitable for various industrial applications. It starts at a price of $40,000.

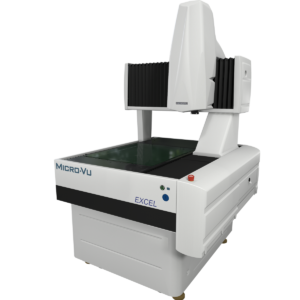

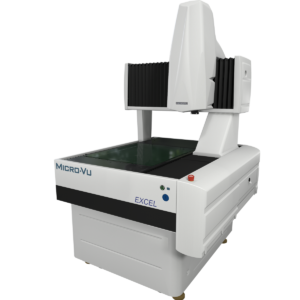

Excel

Starting at 59,400

The Micro-Vu Excel Measuring Center is a gantry stage system designed to deliver fast and precise measurements on a wide variety of parts. Equipped with a high-resolution camera-based measuring system, Excel offers advanced capabilities to meet diverse industrial needs. It starts at a price of $59,400.

Sol

Staring at 17,800

The Sol Vision System introduces cutting-edge technologies to deliver speed and accuracy on a reliable and cost-effective measuring machine. By bridging the gap between manual and automated measurement systems, Sol revolutionizes the way measurements are conducted in various industries. It starts at a price of $17,800.

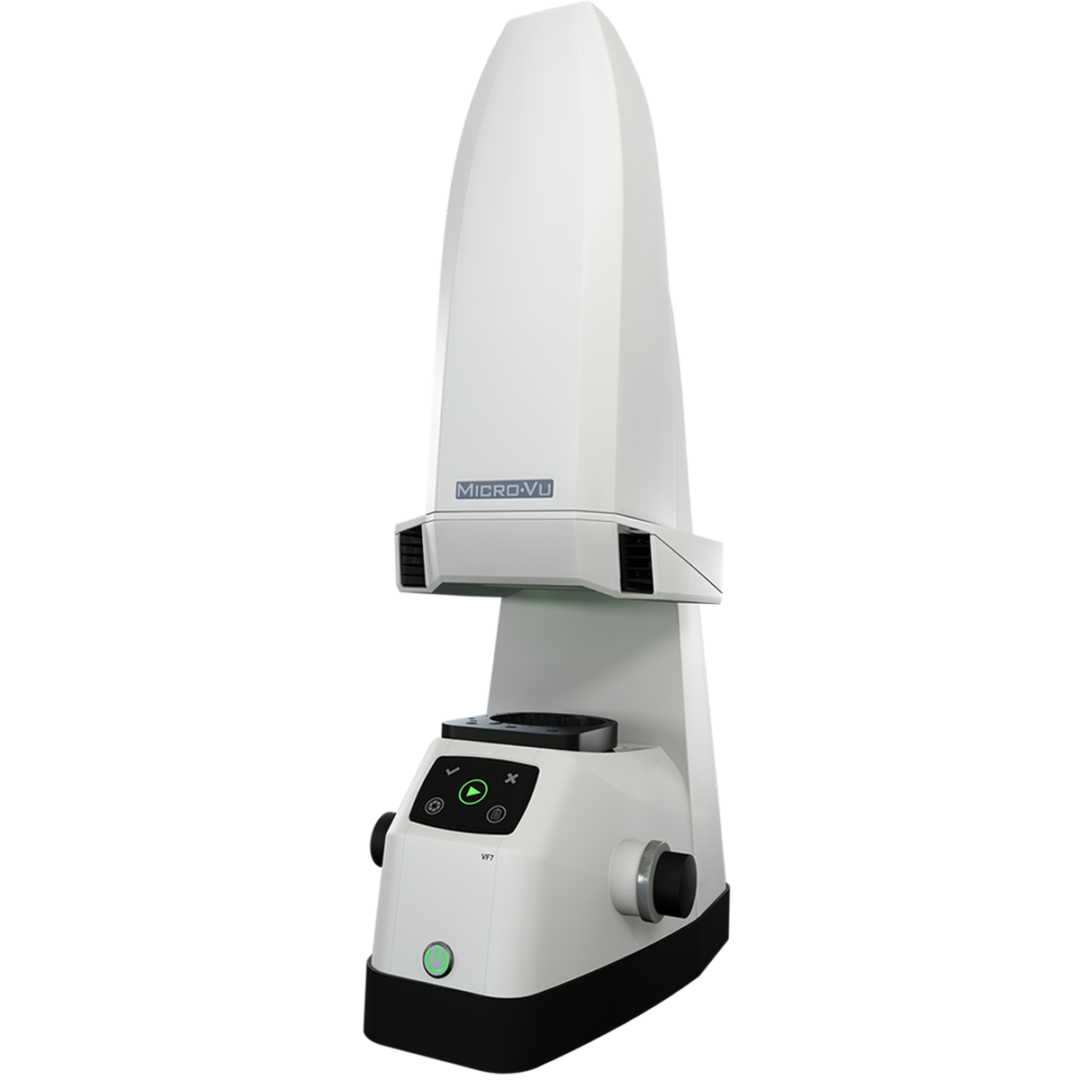

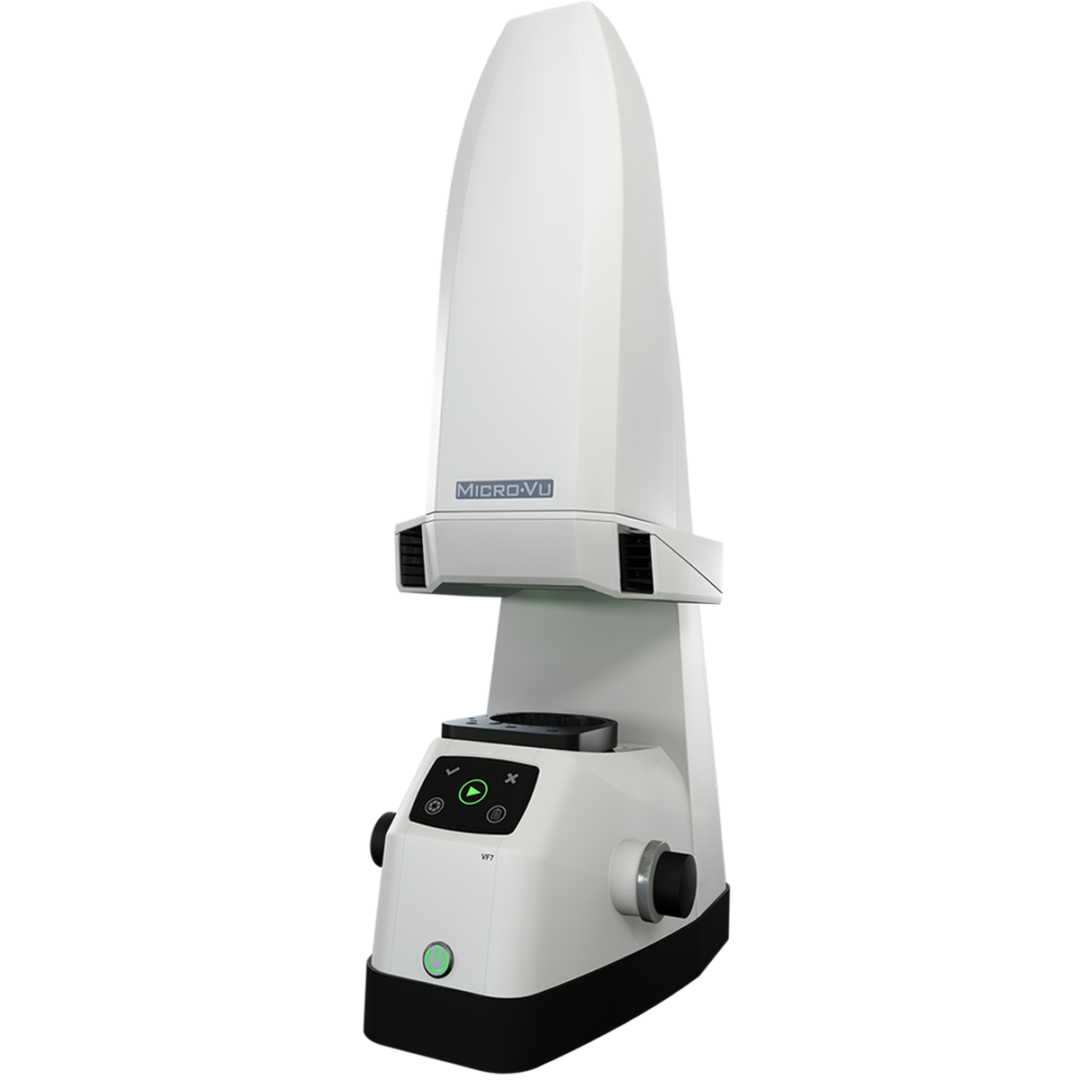

VF7

Starting at $24,400

The VF7 is a high-speed, two-dimensional measurement machine designed for precision with minimal focus adjustments. Its intuitive touch panel allows users to quickly execute and display measurement programs. Powered by Micro-Vu's InSpec Metrology Software, the VF7 features advanced edge detection, multi-sensor integration, and automated calibrations. With high and low image magnification, sophisticated LED lighting, and a single USB connection, the VF7 provides a streamlined, high-accuracy measurement solution.

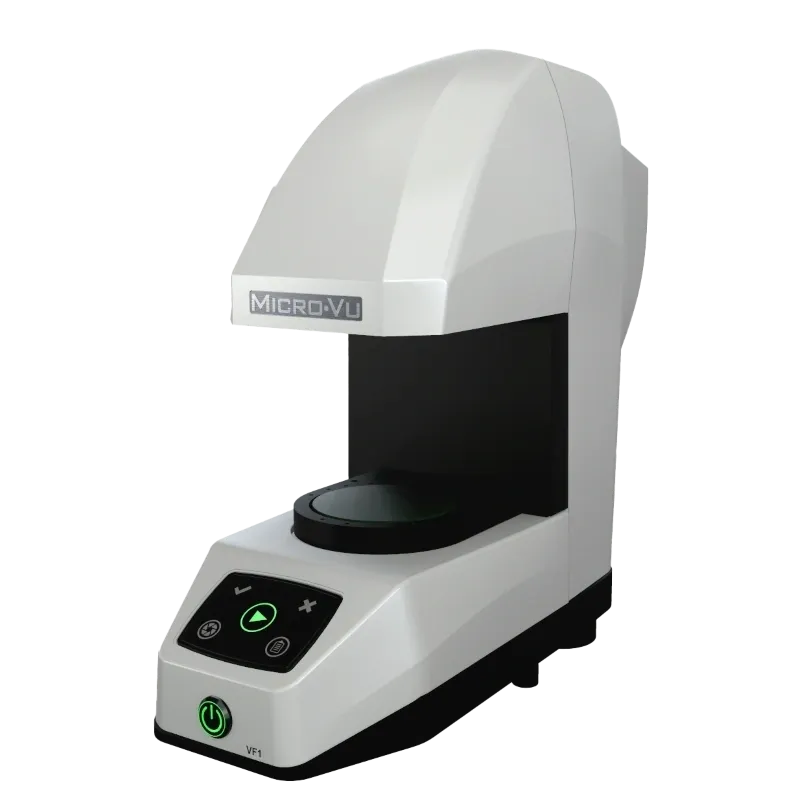

VF1

Starting at $12,300

The VF1 is a compact and high-precision desktop measurement machine ideal for quick and precise measurements without the need for focus adjustments. The VF1's touch panel interface allows users to automatically search for measurement programs, execute them, and display measurement results. The system includes the next generation of InSpec Metrology Software, featuring advanced edge detection algorithms that provide superior performance with sub-pixel accuracy and repeatability. InSpec Metrology Software controls imaging and lighting, resulting in a high-accuracy measurement system. The VF1 features a compact profile light design.

HF5

Starting at $13,660

The HF5 is a fast, two-dimensional, high-precision measurement machine designed with a horizontal layout, making it ideal for measuring cylindrical parts. The HF5's touch panel interface allows users to automatically search for measurement programs, execute them, and display measurement results. The system includes InSpec Metrology Software, image magnification, advanced LED lighting, and features a single USB connection to your workstation computer.