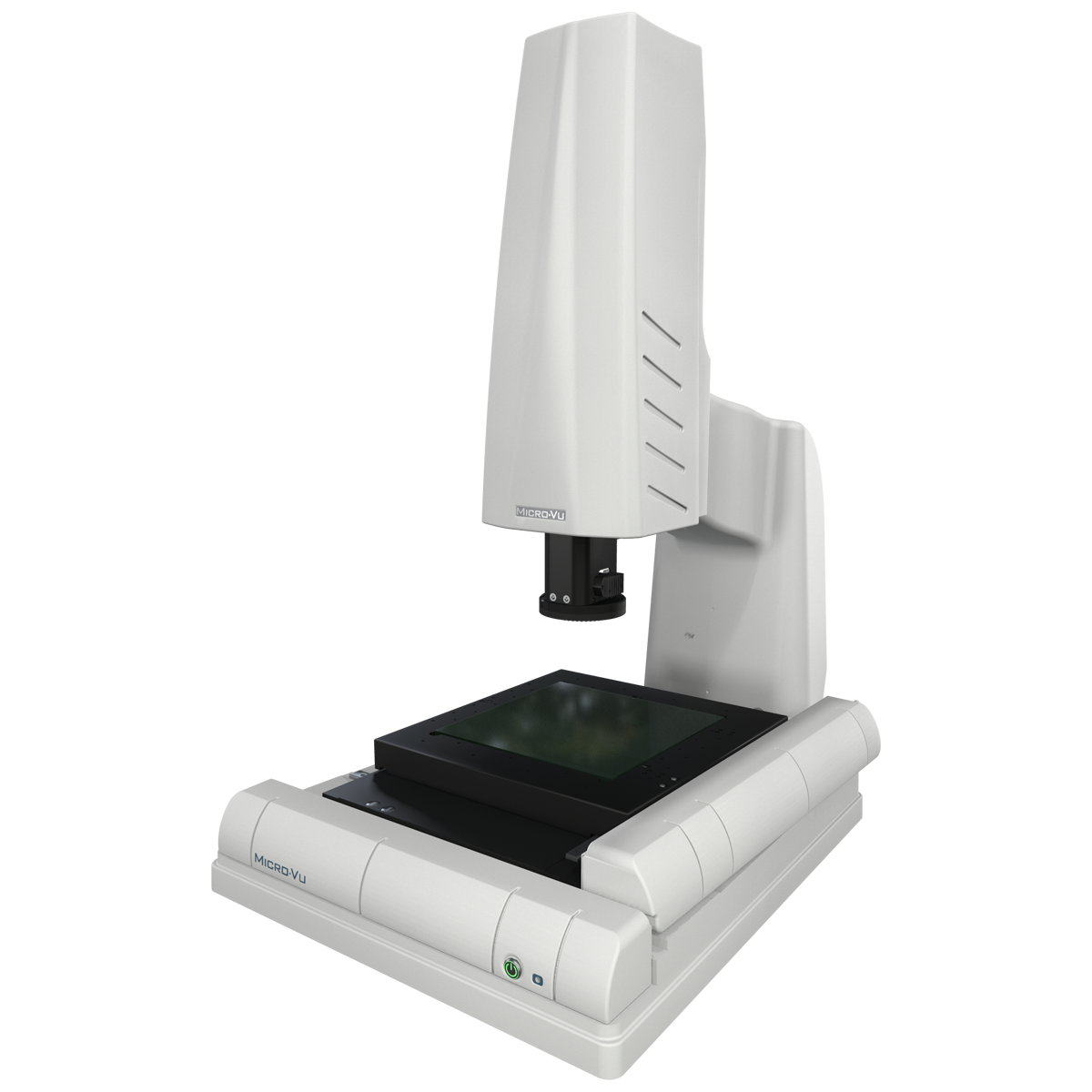

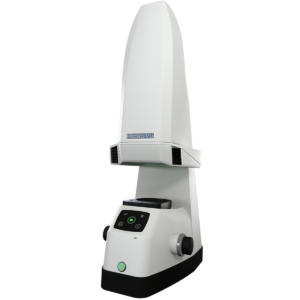

Vertex

The Micro-Vu Vertex Measuring Center is a table top system equipped with a high-resolution camera-based measuring system to get fast, accurate measurements on a wide variety of parts. Vertex can be configured with additional measurement probes and sensors.

Vertex provides vivid pictures through a programmable optical and digital zoom, supports sensitive touch probe accessories allowing measurement of smaller intricate geometry, and high speed vertical distance measurement sensors for scanning capability that covers both specular and diffuse parts.

Vertex includes InSpec Metrology Software, which provides point-and-click simplicity, proprietary edge detection, advanced lighting control and calibration, multi-sensor integration, automated calibrations, and a clear display of measurement data and tolerances.

· Powerful Machine Vision System

· All Systems are Touch Probe and Laser Ready

· All Systems are Rotary Ready

· Programmable optical and digital zoom

· Integrated electronics design, for better system performance and serviceability

· Advanced proprietary motion control ensures high accuracy measurements at high speed

· Programmable profile, surface, and coaxial light

· Integrates high speed vertical distance measurement sensor for scanning capability

Three Sizes:

250 x 160 x 160 mm

315 x 315 x 160 mm

315 x 315 x 250 mm

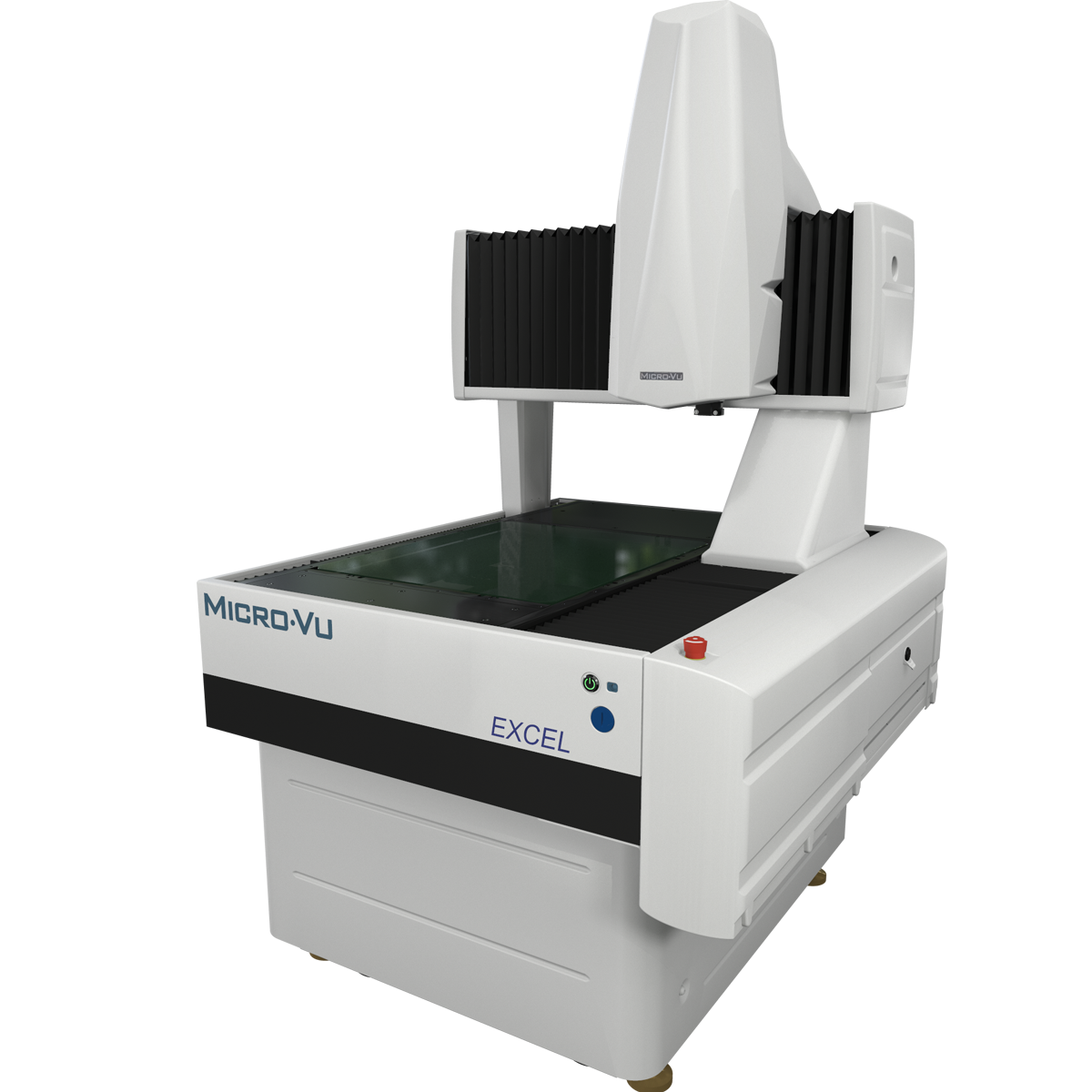

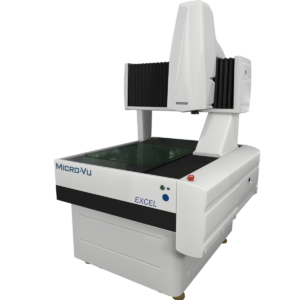

Excel

The Micro-Vu Excel Measuring Center is a gantry stage system equipped with a high-resolution camera-based measuring system to get fast, accurate measurements on a wide variety of parts. Excel can be configured with additional measurement probes and sensors.

Excel provides vivid pictures through a programmable optical and digital zoom, supports sensitive touch probe accessories allowing measurement of smaller intricate geometry, and high speed vertical distance measurement sensors for scanning capability that covers both specular and diffuse parts.

Excel includes InSpec Metrology Software, which provides point-and-click simplicity, proprietary edge detection, advanced lighting control and calibration, multi-sensor integration, automated calibrations, and clear display of measurement data and tolerances.

· Accommodates large parts and fixtures of multiple parts

· All Systems are Touch Probe and Laser Ready

· All Systems are Rotary Ready

· Measures parts up to 2.5 meters long and up to 100 kg

· High resolution digital camera

· Programmable optical and digital camera

· Integrated electronics design, for better system performance and serviceability

· Advanced proprietary motion control ensures high accuracy measurements at high speed

· Programmable profile, surface, and coaxial lights

· Integrates high speed vertical distance measurement sensors for scanning capability

Extra Large Capacities in 15 sizes:

420 x 520 x 160 mm 1050 x 1300 x 160 mm

420 x 520 x 250 mm 1050 x 1300 x 250 mm

660 x 700 x 160 mm 1050 x 1300 x 400 mm

660 x 700 x 250 mm 1250 x 1700 x 160 mm

660 x 700 x 400 mm 1250 x 1700 x 250 mm

750 x 900 x 160 mm 1250 x 1700 x 400 mm

750 x 900 x 250 mm 1600 x 2560 x 160 mm

750 x 900 x 400 mm

Sol

Sol Vision System implements new technologies to provide speed and accuracy on a reliable and affordable measuring machine. Sol bridges the gap between manual and automated measurement systems.

A Programmable 19.5x zoom (6.5x optical and 3x digital), non-linear optics and stage compensation, advanced lighting, and part program compatibility make Sol the most advanced machine in its class.

Micro-Vu’s InSpec Metrology Software drives Sol in addition to manual, vision, and multi-sensor systems. InSpec’s point-and-click measuring and proprietary edge detection simplify demanding measurement applications.

· Surface, Profile, and Axial lighting system

· High – resolution camera-based system to get fast, accurate measurements on a variety of parts

· Vivid pictures through a programmable optical (6.5x) and digital (3x) zoom lens

· Uses proprietary edge detection to capture data

· Multi-Ring, Multi-Sector Ring lights

· Advanced programmable lighting control

· Non-linear stage and optics calibration compensates for systematic variation

· Maintain machine measurement accuracy

· Minimizes factors that cause inaccurate measurements

Three Sizes :

160 x 160 x 160 mm

315 x 315 x 160 mm

315 x 315 x 250 mm

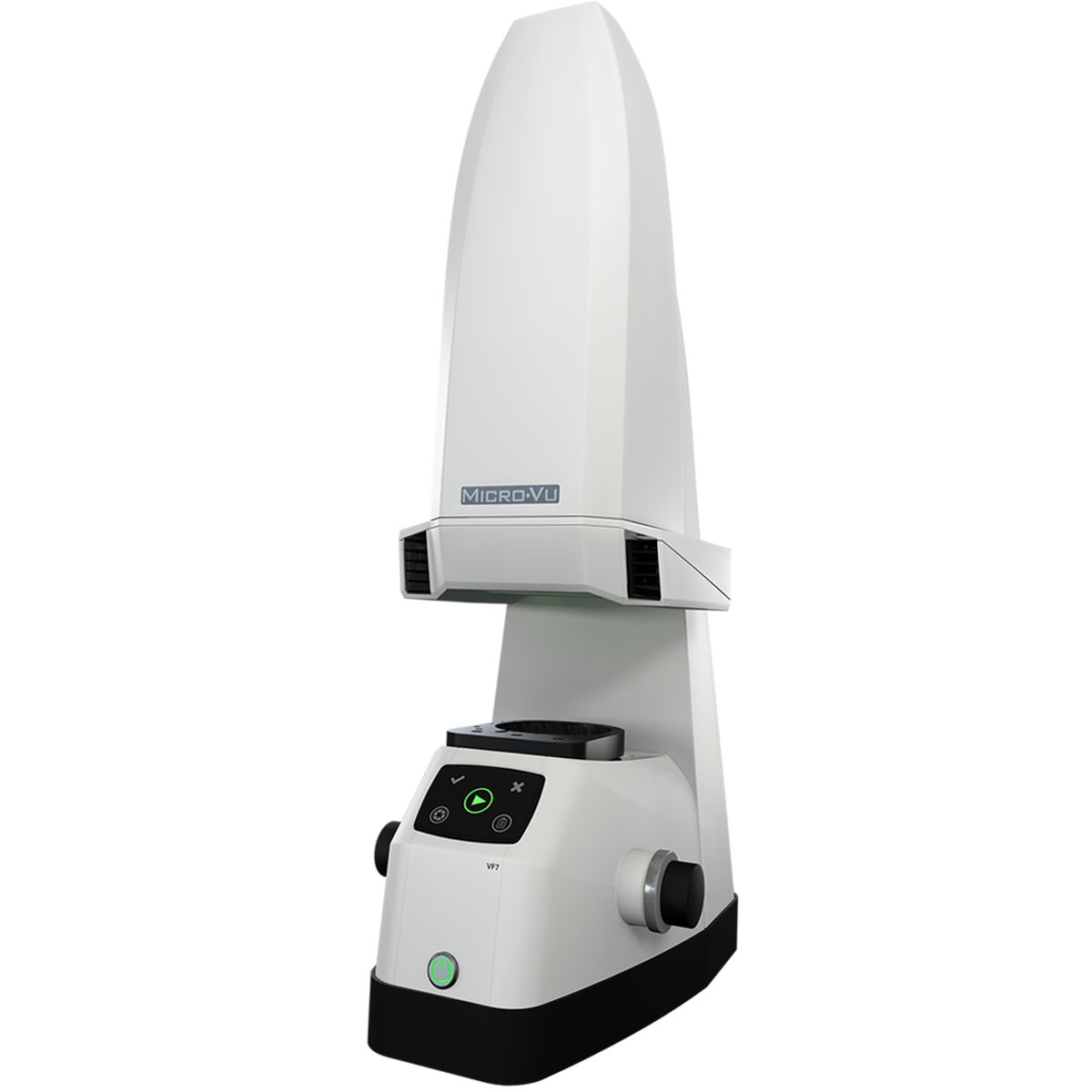

VF7

VF7 is a fast, two dimensional, high precision measurement machine. The system is designed to minimize the need for focus adjustment and part positioning.

VF7 touch panel allows users to automatically search for measurement programs, execute them, and display measurement results.

Micro-Vu’s InSpec Metrology Software provides point-and-click simplicity, proprietary edge detection, advanced lighting control and calibration, multi-sensor integration, automated calibrations, and clear display of measurement data and tolerances.

The system includes InSpec Metrology Software, high and low image magnification, advanced LED lighting, and feature a single USB connection to your workstation computer.

· Low and High Magnification Optical System

· Large Measurement Area

· Large Measurement Range

· Instant Zoom

· Advanced Lighting System

· Automatic Part Identification

· Scratch Resistance Stage Glass

· Single Snapshot Measurement

One Size:

Low Magnification 69.3 x 49.6 mm

High Magnification 17.3 x 12.4 mm