Helmel CMM's & SMM's

Helmel Coordinate Measuring Machines (CMMs) are renowned for their precision, durability, and reliability in the field of dimensional metrology. Designed to meet the rigorous demands of quality control, they offer a versatile range of solutions for accurately measuring components in various industries. With advanced software, robust construction, and user-friendly interfaces, these machines deliver consistent, high-quality performance, making them an essential tool for manufacturers seeking to maintain the highest standards in product quality and precision measurement.

Manual CMM- Helmel Checkmaster

The Checkmaster Manual CMM is a compact and versatile CMM designed for precise inspection on the lab or production floor. Engineered for intrinsic accuracy and ease of installation, the Checkmaster offers reliable performance with minimal thermal error. Its advanced features, including compatibility with Renishaw touch probes and powerful 3D software, make it an excellent choice for quality control in various manufacturing environments. With customizable options and a range of included accessories, the Checkmaster ensures comprehensive inspection capabilities tailored to your specific needs.

Checkmaster CMM Highlights

Specifications

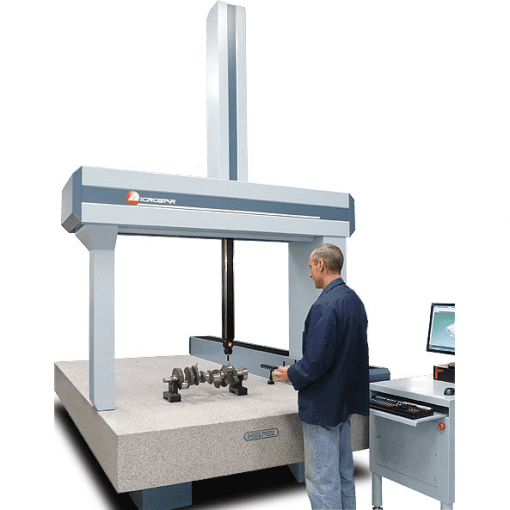

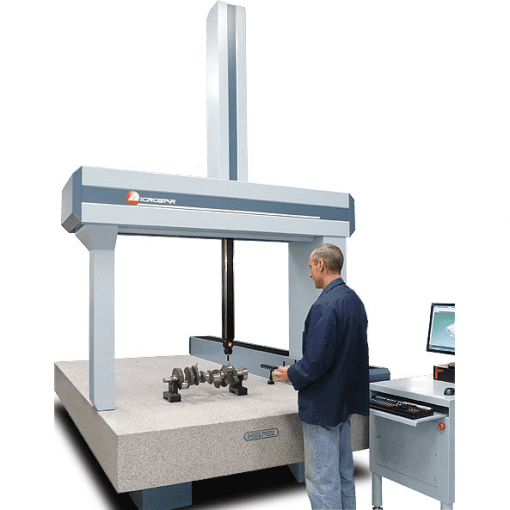

Manual/DCC CMM- Helmel MicroStar

The Microstar series of Coordinate Measuring Machines (CMMs) offers versatile and reliable solutions for both shop floors and labs, accommodating a wide range of sizes from medium to large. Built on a sturdy granite base with a moving bridge design, these CMMs provide exceptional flexibility, accuracy, and structural integrity at a reasonable price. The Microstar series is available in both manual and motorized versions, with features that protect against harsh environments and ensure intrinsic mechanical accuracy without the need for air supplies or complex calibration.

Microstar CMM Highlights

| Model Number | X | Y | Z |

|---|---|---|---|

| 225-162 | 20″ (500) | 25″ (625) | 16″ (400) |

| 325-202 | 25″ (625) | 30″ (750) | 20″ (500) |

| 430-202 | 30″ (750) | 40″ (1000) | 20″ (500) |

| 430-252 | 30″ (750) | 40″ (1000) | 25″ (625) |

| 630-252 | 30″ (750) | 60″ (1500) | 25″ (625) |

| 640-252 | 40″ (1000) | 60″ (1500) | 25″ (625) |

| 840-252 | 40″ (1000) | 80″ (2000) | 25″ (625) |

| 850-252 | 50″ (1000) | 80″ (2000) | 25″ (625) |

DCC CMM- Helmel Microgage

The Microgage CMM offers the highest level of 3D precision in a compact, cost-effective package, making it ideal for small and medium-sized parts. Unlike traditional CMMs that are large and expensive, the Microgage features a rigid fixed bridge design with intrinsic accuracy, ensuring precise measurements without software error correction. Designed for durability and stability, this tabletop CMM is perfect for both lab and production environments, delivering exceptional performance in a small footprint.

Microgage CMM Highlights

Specifications

DCC CMM- Helmel Phoenix

The Phoenix line of Coordinate Measuring Machines (CMMs) combines the robustness of Helmel's proven designs with the convenience of a fully motorized system, making it ideal for demanding shop floor environments. Designed to handle harsh conditions, the Phoenix offers exceptional accuracy and reliability with features like hardened precision-ground ways and dual beam bridge construction. With an ergonomic design and advanced GEOMET software, the Phoenix CMM delivers comprehensive inspection capabilities in a user-friendly package.

Phoenix CMM Highlights

Specifications

DCC CMM- Helmel MicroStar 1M

The Microstar 1M Bridge Type CMM series is engineered for day-in, day-out reliability in large part inspection, embodying Helmel's commitment to quality and precision since 1973. Built with a focus on sound mechanical design and intrinsic mechanical accuracy, these CMMs deliver durable and long-lasting performance. They are easy to operate, affordable, and offer excellent return on investment. With open calibration files and a hybrid bearing system, the Microstar 1M series provides unmatched accuracy and efficiency, making it an ideal choice for high-precision measurements.

Microstar 1M CMM Highlights

Specifications

SMM- Shaft Measurment

The Helmel Shaft Measuring Machines (SMMs) are designed for efficient shop floor measurement of shafts, offering reliable performance and accuracy for decades. Ideal for a wide range of applications, including engine shafts, turbines, transmissions, pumps, and more, these machines provide quick and precise measurements of lengths, steps, grooves, diameters, and run-out. Trusted by leading companies like Xerox, Kodak, GM, Chrysler, John Deere, and Cummins, Helmel SMMs enhance quality control and reduce reject rates, making them a valuable addition to any manufacturing process

Helmel Shaft Measuring Machines (SMMs) Highlights

- Versatile Applications: Suitable for measuring various shaft types in engines, turbines, transmissions, pumps, and more.

- Manual Operation: Available in single or dual-axis configurations, using standard hard mechanical probes.

- High Precision: Non-contact steel scales with .00002″ resolution and intrinsic accuracy from rigid mechanical bearing design.

- Durable Construction: Features hardened ground steel ways and a full granite base on a steel stand for long-term stability.

- Protective Design: All ways, bearings, and scales are enclosed, safeguarding the equipment in shop environments.

- User-Friendly Features: Equipped with Heidenhain ND287 Multifunction position display and fine adjustment on each axis.

- Flexible Lengths: X-axis lengths available from 12″ to 60″ between centers, with longer lengths upon request.

- Customization Options: Offers a range of options, including hand or air-operated centers, adjustable Vee blocks, precision centers, and various specialized probes for specific measurement tasks.

Specifications

Manual Operation, Single or Dual Axes using hard mechanical Probes