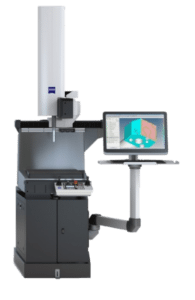

The Reference Machine in the Compact Class

CONTURA – the broad platform from ZEISS for flexible, reliable and uncompromising quality assurance. The latest generation is even more precise and offers a large package of optical sensors on top of a larger measuring range. Outstanding scanning technology, ZEISS CALYPSO reference software and a highly tuned overall concept enable ZEISS CONTURA to cement its place as the standard in its class.

length measurement error E0

from 1.5 + L/350 ?m

Measuring range

| X | Y | Z | |

| 7/7/6 | 700 | 700 | 600 |

| 7/10/6 | 700 | 1,000 | 600 |

| 10/12/6 | 1,000 | 1,200 | 600 |

| 10/16/6 | 1,000 | 1,600 | 600 |

| 9/12/8 | 900 | 1,200 | 800 |

| 9/16/8 | 900 | 1,600 | 800 |

| 12/18/10 | 1,200 | 1,800 | 1,000 |

| 12/24/10 | 1,200 | 2,400 | 1,000 |

The Bridge-Type Measuring Machine, Tailored to your Needs

With its wide range of configurations, the ZEISS ACCURA measuring machine can be tailored to your needs – and budget. Furthermore, the modular design makes the system futureproof: ZEISS ACCURA can be modified to meet changing requirements on the configuration, sensors and software.

Measuring accuracy with the

ZEISS VAST XXT probe system

| Measuring range X x Y x Z [mm] | length measurement error E0 in ?m |

| 900 x 1,200 – 1,600 x 800 | 1.6 + L/350 |

| 1,200 x 1,800 – 4,200 x 1,000 | 2.2 + L/300 |

| 1,600 x 2,400 – 4,200 x 1,000 | 3.9 + L/250 |

| 1,600 x 2,400 – 4,200 x 1,500 | 4.9 + L/250 |

| 2,000 x 2,400 – 4,200 x 1,000 | 5.2 + L/200 |

| 2,000 x 2,400 – 4,200 x 1,500 | 5.5 + L/200 |

Measuring accuracy with the

ZEISS VAST XT gold or

ZEISS VAST gold probe system

| Measuring range X x Y x Z [mm] | length measurement error E0 in ?m |

| 900 x 1,200 – 1,600 x 800 | 1.2 + L/350 |

| 1,200 x 1,800 – 4,200 x 1,000 | 1.9 + L/300 |

| 1,600 x 2,400 – 4,200 x 1,000 | 2.9 + L/300 |

| 1,600 x 2,400 – 4,200 x 1,500 | 3.5 + L/300 |

| 2,000 x 2,400 – 4,200 x 1,000 | 3.3 + L/300 |

| 2,000 x 2,400 – 4,200 x 1,500 | 3.9 + L/300 |

Maximum Precision for Small Parts

ZEISS MICURA sets the standard in the compact class. Despite its small size, ZEISS MICURA makes no compromises when it comes to accuracy. ZEISS MICURA comes standard with the VAST XT gold scanning sensor from ZEISS and navigator technology.

- Ceramic guideways and a large bearing base minimize susceptibility to external influences

- ZEISS air bearings on four sides guarantee stability and precision

- ZEISS MICURA also comes with a temperature sensor for the workpiece

- The probing force of the sensor is actively regulated and is very low – ideal for sensitive materials

- Controller technology, software, sensors and additional components are made by ZEISS and are finely tuned to each other

Sample applications

- Converters and adjusting units with highly accurate leads and bearings

- Pistons and shafts with the tightest tolerances

- Artificial hips

- Gear wheels

- Optical lens elements

length measurement error E0

from 0.7 + L/400 ?m

Measuring range

| X | Y | Z | |

| 5/5/5 | 500 | 500 | 500 |

Ideal for All Measuring Tasks

PRISMO from ZEISS is synonymous around the world for high-speed scanning and maximum accuracy near production. With length measurement error of just 0.5+L/500 millimeters, ZEISS PRISMO ultra is ideal when maximum demands on precision have to be met.

Machine technology

- Bridge made of carbon-fiber compounds and ceramic for minimal weight and high flexural strength

- Temperature-neutral, glass ceramic scales

- All axes with air bearings from ZEISS on four sides. X axis: 8 air bearings; Y axis: 8 air bearings; Z axis: 5 air bearings

- Elastomer vibration damping, as well as covered guideways and scales for use near production

- Workpiece weights up to 5,000 kg

length measurement error E0

from 0.5 + L/500 ?m

Measuring range

| X | Y | Z | |

| 7/9/5 | 700 | 900 | 500 |

| 7/9/7 | 700 | 900 | 700 |

| 9/12/7 | 900 | 1,200 | 700 |

| 9/15/7 | 900 | 1,500 | 700 |

| 9/18/7 | 900 | 1,800 | 700 |

| 9/24/7 | 900 | 2,400 | 700 |

The Reference

ZEISS XENOS is at home wherever maximum precision is demanded – in the measuring labs of research institutes, the aerospace industry and the optical industry. The high-end machine combines precision at the limits of what is technically feasible with a measuring range of nearly one cubic meter.

length measurement error E0

0.3 + L/1,000 ?m

Measuring range

| X | Y | Z | |

| 9/15/7 | 900 | 1,500 | 700 |

DuraMax with shop floor base Shop Floor base

- Dust and moisture protection as per IP54

- Carrier arm for keyboard and monitor

- Lockable storage space for a PC

- Thermal shielding

- Movable with lifting truck or forklift

Optional accessories

- Automatic temperature reader with two workpiece sensors

- Rotary Table

DuraMax HTG

High Temperature Gradient

Deployable from +15ºC to +40ºC

- Enhanced insulating panels

- Extreme temperature stability

- Increased temperature range from +15º C to +40º C

Configuration

In the standard configuration (base, software and hardware), DuraMax HTG corresponds to the model with the Shop Floor base.

The right measuring equipment for the shopfloor.

ZEISS DuraMax eliminates the need for fixed gauges. Equipped with the VAST XXT scanning sensor from ZEISS, it can even be used to capture contours and freeform surfaces. A rough production environment? No match for ZEISS DuraMax.

Further components

- Numerical control panel with two progressive joysticks

- Stylus rack for CNC-guided stylus change

Coordinate measuring technology for production

- Temperature stability from +18ºC to +30ºC

- No compressed air required

- Space-saving design

- Integrated passive damping system

- Four-sided loading

- Completely covered guideways

ZEISS VAST XXT scanning sensor

- Scanning and single-point measuring

- CNC-guided stylus change

- 25 mm adapter plate for optimal reproducibility

- Axial stylus length: 30 to 150 mm

- Radial stylus length: 30 to 65 mm

Compact flexibility.

GageMax measures directly in production with enormous speed and precision. GageMax is unaffected by extreme temperature fluctuations and ground vibrations. GageMax can also measure unknown curves and freeforms via active scanning.

Coordinate measuring technology for production

- Three-sided loading and operation

- Temperature stability from +15ºC to +40ºC

- Compact dimensions, large measuring space

- Moveable with a forklift

- Ram made of temperature-stable carbon-fiber

- Includes stylus rack with 4 slots

- Protective enclosure and safety technology

VAST navigator technology package

- Automatic generation of the ideal measuring strategy

- Tangential approach

- Helix scanning

- Dynamic stylus calibration

VAST performance kit

- FlyScan

- QuickChange

Temperature Variable Accuracy (TVA)

The accuracy of measuring machines is usually only given for the ideal temperature. Not with GageMax: thanks to the TVA formula, the accuracy of this system can be exactly determined for different temperatures.

Options

- Touchscreen – unaffected by oil and dirt

- Pneumatic stylus rack

- Illuminated measuring range

- Rotary table

- Reliable monitoring of the measuring process –choose one of two following options:Monitoring of the GageMax environment (default) or a protected measuring range (alternative)

Unparalleled stability.

CenterMax can be directly integrated into a production line. Vibrations from processing centers are effectively damped. Its variable workpiece base makes it ideal for automated loading.

VAST Performance Kit

- FlyScan

- QuickChange

Options

- Touchscreen – unaffected by oil and dirt

- Pneumatic stylus rack

- Safety equipment

- Rotary table

Coordinate measuring technology for production

- Machine design optimized for integration

- Temperature stability from +15ºC to +40ºC

- Pneumatic vibration insulation

- Robust machine design

Temperature Variable Accuracy (TVA)

The accuracy of measuring machines is usually only given for the ideal temperature. Not with CenterMax: thanks to the TVA formula, the accuracy of this system can be exactly determined for different temperatures.

navigator technology package

- Automatic generation of the ideal measuring strategy

- Tangential approach

- Helix scanning

- Dynamic stylus calibration

The Bridge-Type Measuring Machine, Tailored to your Needs

With its wide range of configurations, the ZEISS ACCURA measuring machine can be tailored to your needs – and budget. Furthermore, the modular design makes the system futureproof: ZEISS ACCURA can be modified to meet changing requirements on the configuration, sensors and software.

Sizes up to: x 2000 mm | y 4200 mm | z 1500 mm

Length measurement error [?m]: From 1.2 + L/350 ?m

Measuring accuracy with the ZEISS VAST XT gold or ZEISS VAST gold probe system

| Measuring range X x Y x Z [mm] | length measurement error E0 in ?m |

| 900 x 1,200 – 1,600 x 800 | 1.2 + L/350 |

| 1,200 x 1,800 – 4,200 x 1,000 | 1.9 + L/300 |

| 1,600 x 2,400 – 4,200 x 1,000 | 2.9 + L/300 |

| 1,600 x 2,400 – 4,200 x 1,500 | 3.5 + L/300 |

| 2,000 x 2,400 – 4,200 x 1,000 | 3.3 + L/300 |

| 2,000 x 2,400 – 4,200 x 1,500 | 3.9 + L/300 |

| Measuring range X x Y x Z [mm] | length measurement error E0 in ?m |

| 900 x 1,200 – 1,600 x 800 | 1.6 + L/350 |

| 1,200 x 1,800 – 4,200 x 1,000 | 2.2 + L/300 |

| 1,600 x 2,400 – 4,200 x 1,000 | 3.9 + L/250 |

| 1,600 x 2,400 – 4,200 x 1,500 | 4.9 + L/250 |

| 2,000 x 2,400 – 4,200 x 1,000 | 5.2 + L/200 |

| 2,000 x 2,400 – 4,200 x 1,500 | 5.5 + L/200 |

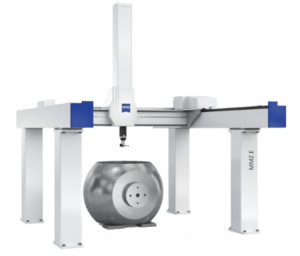

Bridge-Type CMM with Large Measuring Range

With a measuring range of up to 14.8 m³, the ZEISS MMZ T offers the largest measuring range from amongst the table bridge-type measuring machines. For example: it enables the highly precise measurement of large gears directly on the shop floor.

The open design enables easy loading with a crane. The design of the machine allows for workpieces weighing up to ten tons.

Sizes up to x 2100 mm | y 4400 mm | z 1600 mm

Length measurement error [?m]: From 2.4 + L/400 ?m

Measure heavy workpieces efficiently

- Possible to measure workpieces of up to ten tons without a loss of accuracy

- Integrated vibration insulation to prevent the need to construct an expensive foundation

- Bearing technology without compressed air to minimize operating costs

Robust and stable over the long term

- Insensitive to dusty and oily air

- Resistant to rough environmental conditions for reduced demands on the measuring room

- Large bearing clearances and a stable bridge design for exceptional scanning performance

Safety for the operator and the machine

- Kink protection on the ram to protect the sensor/operator

- Optical ram protection to prevent downtimes following a collision

- Safety position for the bridge to ensure safe loading of the coordinate measuring machine with large workpieces

Enlarged measuring performance

- Thermofit XL stylus extensions for measuring very deep boreholes (1,200mm)

- Rotary tables installed in the base to optimally use the measuring range

- Temperature compensation gradients for the axes to selectively capture temperature differences

Technical data summary

| Length measurement error: | MPE_E150 | from 2.4 + L/400 ?m |

| Single stylus probing error: | MPE_PFTU | from 2.0 ? |

| Scanning probing error: | MPE_THP/tau | from 2.8 ? / 62 s |

| Form measuring error: | MPE RONt | from 2.0 ?m |

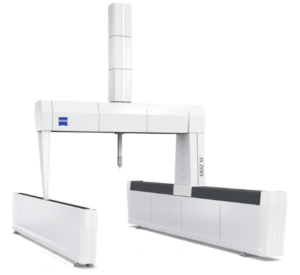

Gantry CMM with Large Measuring Range

ZEISS MMZ E gantry measuring machines are ideal for inspecting workpieces which are transported via floor conveyors because these measuring machines offer open access from all four sides. Crane loading can also be easily performed.

MMZ E measuring machines from ZEISS are used, for example, in the mechanical engineering, automotive and aerospace industries and for the inspection of satellite technology. They are particularly well-suited for the inspection of large workpieces.

Sizes up to: x 2500 mm | y 6000 mm | z 1800 mm Custom lengths possible

Length measurement error [?m]: From 3.3 + L/230 ?m

Future-proof and high-quality

- Articulating probe holder for maximum flexibility and minimizedcosts with measuring styli

- Optical sensor for capturing freeform surfaces

Safety for the operator and the machine

- Light barrier around the measuring machine to protect the operator when they enter the measuring range

- Safety position for the bridge to ensure safe loading of the coordinate measuring machine with large workpieces

Ergonomically-correct work

- All-sided view of measuring range

- All-sided access for crane loading

- Wireless control panel for ergonomic operation

Additional configurations

- Aluminum ram for a cost-effective entry-level configuration

- Ceramic ram for precise, active scanning

Technical data summary

| Length measurement error: | MPE_E150 | from 3.3 + L/230 ?m |

| Single stylus probing error: | MPE_PFTU | from 3.0 ? |

| Scanning probing error: | MPE_THP/tau | from 3.5 ? / 70 s |

| Form measuring error: | MPE RONt | from 4.0 ?m |

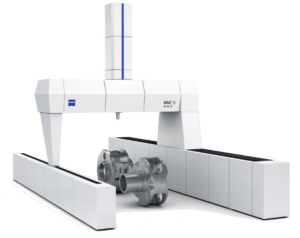

Bridge-Type CMM for Complex Workpieces

Precise measurements at favorable acquisition costs – this was the goal when developing the ZEISS MMZ M. The coordinate measuring machine is ideal for checking complex workpieces, especially those with tight tolerances.

ZEISS MMZ M CMMs are used by mechanical engineers as well as windturbine and gear train manufacturers.

Sizes up to: x 3000 mm | y 6000 mm | z 2000 mm

Length measurement error [?m]: From 2.2 + L/400 ?m

Efficient, highly precise measurements

- Resistant to harsh environmental conditions for minimal demands on the measuring room

- Large bearing clearances and a stable bridge design for an exceptional scanning performance

- Thermofit XL stylus extensions for measuring deep boreholes (1,200mm)

Ergonomically-correct work

All-sided view of the measuring range

Walk-in measuring area for effective analysis directly on the workpiece

Mobile data station for direct programming on the workpiece

Low infrastructure costs

Minimal footprint compared with measuring range to minimize the amount of space required

Minimized foundation requirements to reduce costs for the foundation

Articulating probe holder for maximum flexibility and minimized costs with measuring styli

Future-proof and high-quality

ZEISS VAST navigator probe system to quickly calibrate, scan and increase precision

ZEISS VAST performance to increase measuring throughput

Technical data summary

| Length measurement error: | MPE_E150 | from 2.2 + L/400 ?m |

| Single stylus probing error: | MPE_PFTU | from 1.7 ? |

| Scanning probing error: | MPE_THP/tau | from 2.2 ? / 64 s |

| Form measuring error: | MPE RONt | from 2.0 ?m |

Bridge-Type CMM for Large Workpieces

Large bridge-type machines in the ZEISS MMZ G line meet the highest demands: they feature the largest measuring range of all measuring machines offered by ZEISS and offer you unparalleled accuracy.

This makes the ZEISS MMZ G ideal for checking complex, extremely large workpieces, especially those with tight tolerances. ZEISS MMZ G measuring machines are used by manufacturers of printing machines, wind turbines and in mechanical engineering.

Sizes up to: x 6000 mm | y 11000 mm | z 3500 mm

Linear measuring error [?m]: From 2.2 + L/400 ?m

Measure extremely heavy workpieces dependably

- Resistant to harsh environmental conditions for minimal demands on the measuring room

- Large bearing clearances and a stable bridge design for an exceptional scanning performance

- Workpiece weight limited only by the thickness of the foundation

Ergonomically-correct work

All-sided view of the measuring range

Walk-in measuring area for effective analysis directly on the workpiece

Mobile data station for direct programming on the workpiece

Minimized subsequent costs

Durable thanks to the robust roller bearings

Minimal expenses for worn parts because of transverse force-free drives

Extremely sturdy because of its very stable mechanical design

Exceptional scanning performance

ZEISS VAST navigator to quickly calibrate, scan and increase precision

ZEISS VAST performance to increase measuring throughput

Thermofit XL stylus extensions for measuring deep boreholes (1,200mm)

Technical data summary

| Length measurement error: | MPE_E150 | from 2.2 + L/400 ?m |

| Single stylus probing error: | MPE_PFTU | from 2.0 ? |

| Scanning probing error: | MPE_THP/tau | from 2.8 ? / 62 s |

| Form measuring error: | MPE RONt | from 2.0 ?m |

Exclusive features for a wide range

ZEISS CARMET is an economical, all-inclusive package that leaves nothing to be desired and offers ZEISS quality throughout.

length measurement error E0

From 35 + L/50 ? 80 [?m]

At 16-24°C

Flush-floor access

With the flush-floor model, ZEISS CARMET offers free access from all sides. An onfloor version is available for use with an existing foundation.

Precision and dynamics

The ZEISS CARMET Z column has a trapezoidal shape. A wide base provides

stability and rigidity for maximum precision. The upward taper saves on weight, which benefits the dynamics. In this way ZEISS CARMET combines precision and dynamics in a superior design.

Linear guideways with ball chains

Linear guideways with ball chains ZEISS sets in all axes linear guides with

ball chains, which are characterized by high rigidity, smooth operation and low

maintenance.

Integrated control

ZEISS CARMET is controlled by a moving control unit integrated in the measuring machine. This reduces the number of interfaces, speeds up the installation process, and reduces space requirements. The control unit housing also serves as a holder for the control panel.

Single measuring ranges [mm]

| Type | X | Y | Z |

| 40/16/25 | 4000 | 1600 | 2500 |

| 50/16/25 | 5000 | 1600 | 2500 |

| 60/16/25 | 6000 | 1600 | 2500 |

| 70/16/25 | 7000 | 1600 | 2500 |

Safety

The horizontal arm of the ZEISS CARMET is equipped with space-saving collision protection on both sides to protect people and material from injury and damage. The proven friction drives in the ZEISS machines that simply slip through when there is a blockage also contribute to safety.

Temperature stability

For all structurally relevant components, ZEISS consistently uses steel, which allows for even, controlled heat expansion. In addition, the Z column is also thermally insulated by F.I. technology. The result: The machine can be used in a broad temperature range from 16 to 24°C within the specified measuring error. Furthermore, the machine does not have to be cooled, and temperature compensation is not required. In addition, the light insulation cover can be removed quickly and easily for maintenance.

Options and accessories

- On-floor machine

- Wireless control panel

- Swiveling control unit with TFT monitor, keyboard, trackball and control panel holder for programming directly at the measuring point

- ZEISS FalconEye optical sensor system

Duplex measuring ranges [mm]

| Type | X | Y | Z |

| 40/30/25 | 4000 | 3000 | 2500 |

| 50/30/25 | 5000 | 3000 | 2500 |

| 60/30/25 | 6000 | 3000 | 2500 |

| 70/30/25 | 7000 | 3000 | 2500 |

Fully configurable for your convenience

The ZEISS PRO is a modular horizontalarm measuring machine that is very easy to configure and available in two versions: PRO advance and PRO premium. This means that it can be ideally tailored to meet your cost efficiency and performance requirements.

Model versions

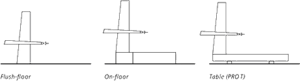

ZEISS PRO is available in three models:

- The flush-floor version allows safe, unobstructed access from all sides.

- The on-floor version can be placed on an existing foundation.

- The table model (PRO T) offers the best independence from a foundation because the table itself provides a rigid, stable base.

Each version can be equipped with one arm or a dual arm.

length measurement error E0

(Y = 1600 mm, Z = 2100 mm)

Base configuration

From 27 + L/80 ? 70 [?m]

At 16-24°C

Premium equipment

From 18 + L/125 ? 50 [?m]

At 18-22°C

ZEISS PRO premium

The ZEISS PRO premium bundles all the performance features that are available for the PRO series in one package. Full enclosure, automatic temperature compensation and the best possible accuracy and speed are indispensable components of the ZEISS PRO premium.

A ZEISS PRO advance with all the premium options is identical to a ZEISS PRO premium.

Other options and accessories

- Anti-kink protection for the articulating probe holder

- Wireless control panel

- Mobile control unit with TFT monitor, keyboard, trackball and control panel holder for programming directly at the measuring point

- ZEISS EagleEye optical sensor system

ZEISS PRO advance

Advantages of ZEISS PRO are:

- Trapezoidal stand and horizontal arm for maximum precision and dynamics

- Collision protection on both sides

- Flush-floor access to measuring range from all sides

- Continuous CSC articulating probe holder with high torque and high dynamics

- Easy access to maintenance-relevant parts

- Anti-kink protection for sensor carriers, optional

- ZEISS EagleEye optical sensor for significantly shorter measuring time

These premium options can be added to the ZEISS PRO advance as required:

- Full enclosure to protect against dirt and for thermal insulation

- Temperature compensation for greater accuracy in the event of variations in temperature

- “Performance option” for 50% greater maximum acceleration

- “High accuracy” option for approximately 30% less measuring error (in combination with full enclosure and temperature compensation)