Vision Fixturing

Enhance your inspection processes with RFM's advanced vision fixtures. Our innovative solutions are designed to increase productivity and accuracy by providing fast, repeatable ways to fixture parts for consistent inspections. Explore our range of vision fixtures to find the perfect fit for your needs.

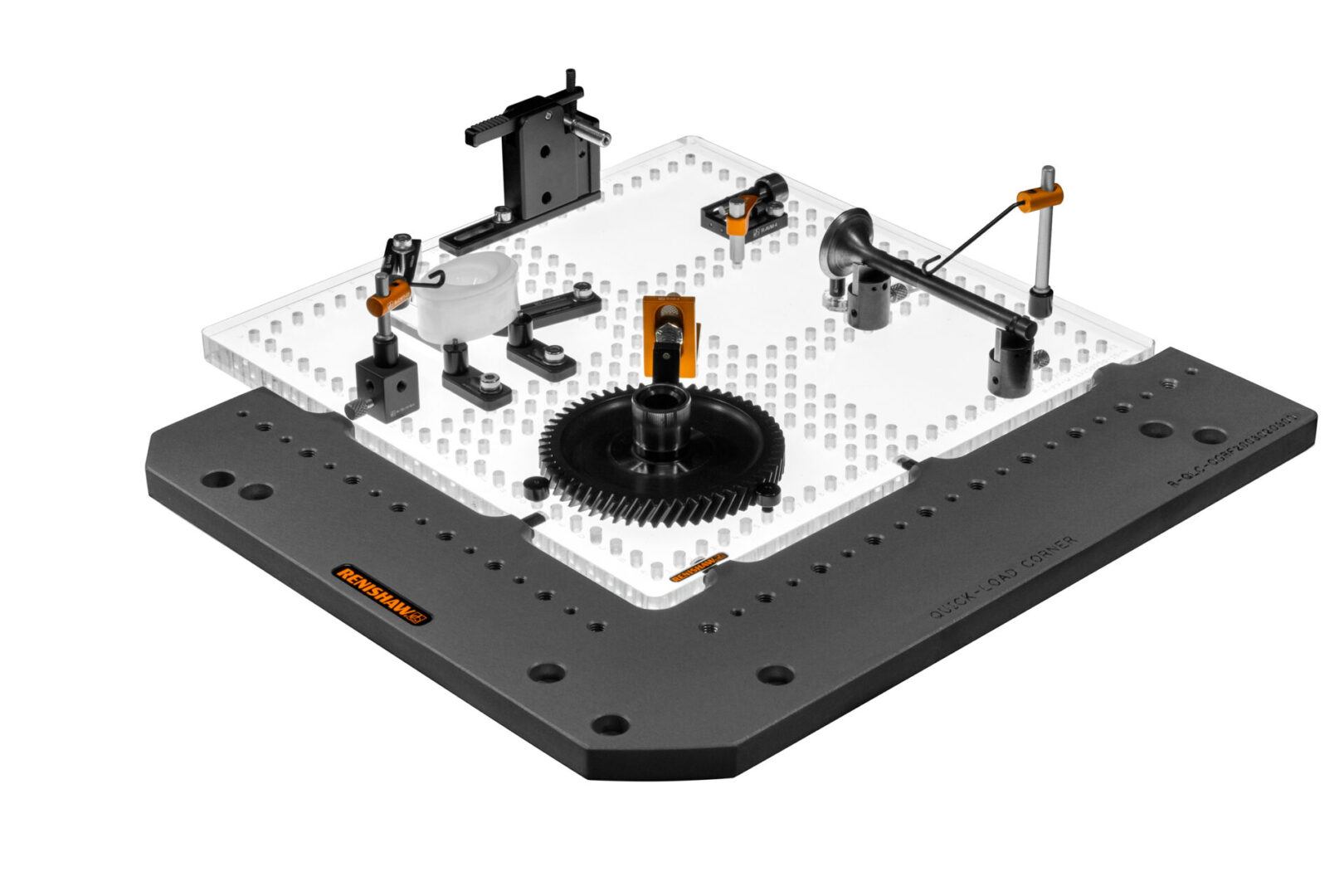

Quick-Load Corner (QLC) Vision Fixtures

The R&R Quick-Load Corner (QLC) vision fixture offers a fast, repeatable method to fixture parts for inspection, ensuring consistent results every time.

- Custom Fit: Available in various sizes and shapes to match your vision machine.

- Easy Positioning: Features dowel pins and magnets that snap together for precise, repeatable placement.

- Versatile Holding: With multiple holes and various components, it can hold virtually anything with minimal contact or force.

Vision Fixture Kits

Our comprehensive vision fixture kits are perfect for holding steel, aluminum, plastic, and other ferrous and nonferrous parts.

- Complete Kits: Each kit includes an acrylic base plate with M4 or 1/4-20 threaded holes and a full set of components.

- Customizable Options: Choose the thread and plate size that fits your stage or fixturing application, along with small or medium component kits.

- Extensive Selection: Components and plates can also be purchased separately, offering more fixturing options than any other company.

Vision Fixture Plates

Choose from either an acrylic Multi-Window or Multi-Hole Vision plate, both featuring an alpha-numeric labeled grid pattern.

- Consistent Setup: Enables repeatable part setups each time for reliable inspections.

- Multi-Part Accommodation: Designed to hold many parts at once, with different sizes to fit your stage.

- Optimal Viewing: Small fixturing components allow complete viewing access without covering critical features, perfect for parts 75mm x 75mm (3″ x 3″) or smaller.

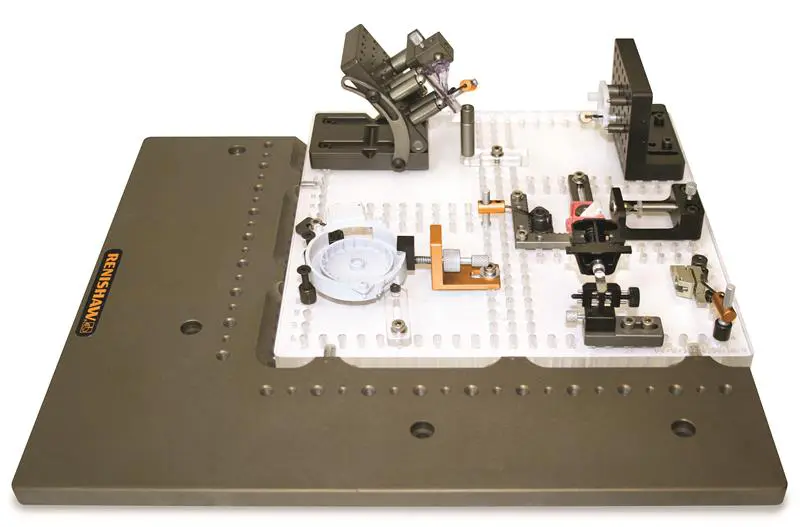

Interchangeable Vision Fixtures

Our interchangeable vision fixtures feature an anodized aluminum frame and your choice of modular or custom acrylic base plates, designed for specific vision machines.

- Perfect Fit: Ideal for machines 400 x 400 or larger, accommodating probe racks and calibration artifacts as needed.

- Repeatable Positioning: Quickly load and unload plates into the frame in a consistent, repeatable position.

- Efficiency: Ideal for multiple users or parts inspected repeatedly, providing an efficient turnkey fixturing solution.

Vision Custom Fixtures

Leverage our extensive experience to design and build custom fixtures tailored to your specific needs.

- Expert Design: Our expertise in backlighting and touch probes ensures accurate, first-time fixtures.

- Customer-Focused: We continuously adapt to meet customer demands, enhancing productivity and profitability.

- Quality Assurance: Expect superior quality and performance from our custom fixtures.

Transform your inspection processes with RFM's vision fixtures, designed to deliver precision, efficiency, and versatility for all your metrology needs.